Safer every day

Technology and the evolution of mining

There’s no question that mining is safer today than ever before. This holds worldwide and is very evident in Australia. Many articles have been written about the growth in Australian mine safety culture over the past twenty years and sad reflections on what went wrong in 2018 and 2015 – but mine safety progress is a story far longer than twenty years.

In this blog post we take a look at where and how Measure Australia has directly worked with mine sites and after that dive into the history of mine safety in Australia generally, and how technology has historically been a part of a 200+ year journey to mining safety.

Technology is making mining jobs safer

The Australian mining industry is becoming ever safer as new technologies are adapted into processes at mine sites across the country. Autonomous machinery and processes have been central to this, keeping people out of hazardous zones entirely. Measure Australia has been on the forefront of this change, commencing drone data collection in 2007.

Our CEO Aonghus Stevens said he spent a long weekend in 2019 classifying work orders, and came up with just more than 200,000 separate times that Measure’s projects had kept people and teams from entering hazardous locations – that is statistically likely to have kept quite a number of people from accidents and possibly fatality.

Measure Australia’s work with mine sites includes:

-

Stockpile measurement management

-

Asset inspection (buildings and facilities)

-

Asset audit (heavy equipment)

-

Exploration mapping

-

Pit mapping

-

Autonomous vehicle integration

Aonghus said that each of these project types keeps mine employees away from potentially unsafe situations, which overall makes mines safer. He added that these same tech opportunities and advances are improving site productivity, and while some commentators have criticised safety culture as significantly responsible for production drops in the past twenty years, autonomous data collection has more than made up for that. “The efficiency gains made possible by integrating true data-driven site operations are manifest, and improvements down the entire supply chain amplify those even more,” he said.

A brief history of mines (and some vice)

Australia’s mining history stretches back to first nation Aboriginal peoples digging for pigments to use in rock and body art – there’s evidence of particular interest in the unusual minerals found in the Kimberley.

Australia's 7th largest city is ... Kingstown?

The first location valuable buried minerals were discovered by European settlers was a place Kingstown, in June 1801 by Lieutenant-Colonel William Patterson. Kingstown is today the site of Australia’s 7th largest city – haven’t heard of it? Not surprising – the discovery of coal led Governor King to promptly and somewhat unimaginatively rename it Newcastle, after the huge English coal mining town of the same name in England.

Coal & convicts

The Crown and governor were overjoyed to discover coal at Newcastle, particularly since they were bursting at the seams with convicts to go mine it without payment. Trial digs soon revealed that most of the eastern seaboard is built on coal. Within a month Governor King had established a penal settlement, with the express goal of segregating those troublesome, but adept coal mining, Irish. These convicts initially worked without wheelbarrows and regular tools, and after barrows were provided were made to shift 100kg+ loads. That penal settlement mine was closed rather quickly, due to the undocumented ‘improper behaviour’ of the settlement leader and surgeon Martin Mason. One wonders.

Mines in that era were not very safe, but limited records regarding WHS were kept in that time. What does seem clear is that, as dangerous as coal mining in particular was at that time, poor treatment of convicts was the more common vector of abuse. A new penal mine quickly opened at Newcastle – can’t let that coal go to waste! Or the labour! Now under crown appointee Charles Throsby, Newcastle’s coal mining convicts:

-

Were tired. Worked from sunrise at 6am until sunset at about 5:50pm, with 30 mins for breakfast at 8am and a very civilised two hour lunch break (they had to cook their lunch in that time).

-

Were hungry. Insufficient food was provided because a) nobody cared overly about convicts stomachs and then b) a series of calamities spoiled stores and the convict’s crops. Note that convicts worked on growing these crops without missing a beat at the mine.

-

Were cold. Convicts were given clothing insufficient to the temperatures and weather they faced.

-

Were in the dark. Convicts were not given lamp oil.

Convict mines existed from Tasmania through Queensland, and later in the West. They were unsafe with little medical attention available. It does seem true that the ill treatment was because the miners were convicts, rather than because they were miners, and conditions were probably less outrageous than in the United States 100 years later.

Eureka, it’s gold!

That shiniest of metals, gold, was discovered in New South Wales in 1851 and not much later in Victoria, and Western Australia got in on the action in no time. Gold was everywhere.

Where gold was panned or shallow dug, the miners suffered little by way of direct occupational safety issues outside those of everyday life in the time (such as horse riding or exposure to unknown noxious flora). The conditions that these miners lived in, however, made the occupation extremely dangerous. The threats of just living included:

-

Typhoid (a multi-year epidemic, with reports of 20% of mining camp populations dying)

-

Fires (structures and mining infrastructure was made of wood)

-

Lack of water (Australia)

As digs became deeper and ownership consolidated, the threat of fires moved from accommodation to the shafts. New mining processes exposed miners to a lot of very fine rock powder that caused direct medical issues and increased the risk of tuberculosis and other chest ailments.

The Western Australian government kept records of this period that include fatalities – while one cannot be certain they are complete, the relative difference is huge;

1894: 4 fatalities

1899: 45 fatalities (38 underground)

These were considered sufficiently important that two Royal Commissions were called within a few years – the Royal Commission on Ventilation and Sanitation of Mines in 1905, and the Royal Commission into Pulmonary Diseases Amongst Miners in 1910.

Australia has resources?

More and more minerals were found in Australia. Tasmanian Tin, Queensland copper, and a few others without alliteration – silver and zinc in New South Wales, the massive goldfields of Kalgoorlie deserve note again, iron ore in South Australia. Uranium in SA, NT and then everywhere else.

Oddly enough mining activity declined until the early 1960s, partially because Australia was happy farming and riding on the sheep’s back and partially because the sheer scale of the deposits mostly weren’t realised.

This refocus on mineral extraction in the 1960s heralded the intensive industrialisation of mining.

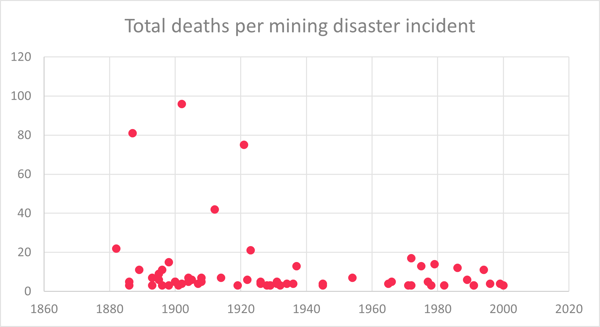

Fatalities

One lense through which to view mining safety is fatalities. Incomplete records were kept throughout the 19th and 20th centuries, but there are some worth noting. Australian mining disasters, defined as incidents with 3+ fatalities, from 1880 to 2000 reflect safety improvements over time.

The incidence of disasters more than halved from the 1960s onward, and the average number of fatalities per incident halved.

|

Incidents |

Av. incidents per decade |

Fatalities |

Av. Fatalities per incident |

|

|

Pre 1960s |

45 |

11 |

550 |

12 |

|

1960s onward |

19 |

5 |

123 |

6 |

The incidence of massive mass-fatality events also reduced, with ~100 fatality events clustered around the turn of the 20th century.

|

Incidents |

Fatalities |

Av. Fatalities per incident |

|

|

Metal mining |

20 |

154 |

8 |

|

Coal mining |

44 |

512 |

12 |

|

All |

63 |

666 |

11 |

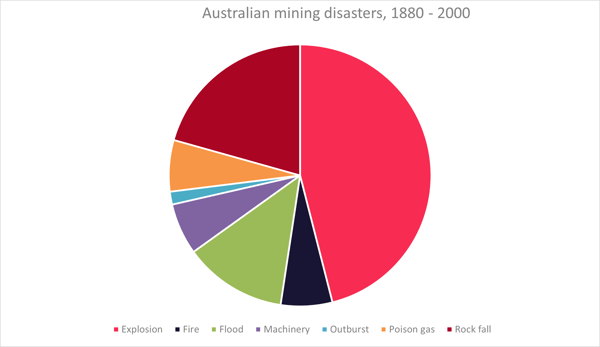

Australian mining disaster causes 1880-2000

Australian mining disaster causes 1880-2000

Combining the number of incidents, number of fatalities and breaking those out by coal mining and metals mining demonstrates that fatalities halved in from the 1960s onwards. Disasters at coal mines did not drop to the extent that metals mining did, but the statistical view of increased safety is clear – mining in Australia became significantly more safe from the 1960s onward to 2000.

|

Incidents |

Av. incidents per decade |

Fatalities |

Av. Fatalities per incident |

|

|

Metal pre 1960 |

15 |

2 |

133 |

9 |

|

Metal 1960+ |

5 |

1 |

21 |

4 |

|

Coal pre 1960 |

30 |

4 |

417 |

14 |

|

Coal 1960+ |

13 |

3 |

95 |

7 |

|

Total pre 1960 |

45 |

6 |

550 |

12 |

|

Total 1960+ |

18 |

5 |

116 |

6 |

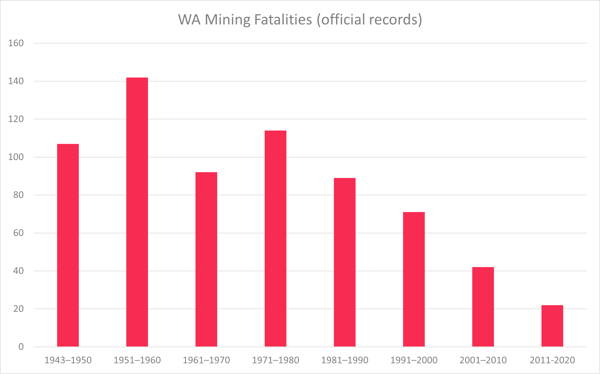

Western Australia has recorded mining fatalities since 1940, and it also demonstrates a clear reduction in fatalities both over time and with an accelerated reduction since the industrialisation of Australian mining and up to the present day (note that 2020 numbers are YTD).

WA mining fatalities based on official government records

WA mining fatalities based on official government records

With that background it is clear that today’s safety gains stand on the shoulders of past miners. Figures released by the WA Dept of Mines, Industry Regulation and Safety demonstrate this (even given the 2018 tragedies). Since 1997 – important as the year in which WA tightened WHS regulations – there’s been a 72% reduction in injuries and fatalities, reflected in the last graph.

It isn’t just regulations though – the three main factors in improved WA (and Australian, more generally) conditions are regulations, culture and technology. Which is where Measure Australia has a hand! Initiatives such as enforcing drug and alcohol policies are a good example – regulations regarding intoxication are not new. Safety and Health Act 1984 (the OSH Act) and the Mines Safety and Inspection Act 1994 (the MSI Act) for example detailed individual, managerial and collective responsibilities associated with intoxication. However, anecdotally, many old mining hands will talk about the pervasive culture of working while undoubtedly over the limit after a big night and even drinking during shift. That regulation mirrored and bolstered a cultural shift. And advancing technology made it practical to easily screen for alcohol and other intoxicants – regulations, culture and tech combined to require a change, popular support for the change and a mechanism to enforce compliance.

Regulation + Culture + Technology = Safety Gains

Regulation + Culture + Technology = Safety Gains

Technology is making mining jobs safer

The Australian mining industry is becoming ever safer as new technologies are adapted into processes at mine sites across the country. Autonomous machinery and processes have been central to this, keeping people out of hazardous zones entirely. Measure Australia has been on the forefront of this change, commencing drone data collection in 2007.

Our CEO Aonghus Stevens said he spent a long weekend in 2019 classifying work orders, and came up with just more than 200,000 separate times that Measure’s projects had kept people and teams from entering hazardous locations – that is statistically likely to have kept quite a number of people from accidents and possibly fatality.

Measure Australia’s work with mine sites includes:

-

Stockpile measurement management

-

Asset inspection (buildings)

-

Asset audit (heavy equipment)

-

Exploration mapping

-

Pit mapping

-

Autonomous vehicle integration

Aonghus said that each of these project types keeps mine employees away from potentially unsafe situations, which overall makes mines safer. He added that these same tech opportunities and advances are improving site productivity, and while some commentators have criticised safety culture as significantly responsible for production drops in the past twenty years, autonomous data collection has more than made up for that. “The efficiency gains made possible by integrating true data-driven site operations are manifest, and improvements down the entire supply chain amplify those even more,” he said.